Stirtec GmbH is a leading high-tech company in the field of Friction Stir Welding (FSW), located in Premstätten, Styria (Austria). Stirtec was initially established in 2010 as a spin-off of Graz University of Technology in the Science Park Graz to exploit the commercial potential of the Friction Stir Welding technology for industrial applications. Based on more than 10 years of scientific research resulting in five patents, and together with the successful implementation of various industrial projects in close customer cooperation, Stirtec is now a leading solution provider in the field of FSW.

As a pioneer for joining so far nonweldable metals (dissimilar materials, such as steel and copper and high strength steels), the company is offering machines, software and tools for demanding applications to European and US customers. Stirtec has established an initial client base of satisfied reference customers in both the transportation and industrial sectors, securing high trust in the company. Stirtec wants to be the clear market leader in Europe for friction stir welding for industrial applications, serving globally active customers.

Stirtec GmbH is a leading high-tech company in the field of Friction Stir Welding (FSW), located in Premstätten, Styria (Austria). Stirtec was initially established in 2010 as a spin-off of Graz University of Technology in the Science Park Graz to exploit the commercial potential of the Friction Stir Welding technology for industrial applications. Based on more than 10 years of scientific research resulting in five patents, and together with the successful implementation of various industrial projects in close customer cooperation, Stirtec is now a leading solution provider in the field of FSW.

As a pioneer for joining so far nonweldable metals (dissimilar materials, such as steel and copper and high strength steels), the company is offering machines, software and tools for demanding applications to European and US customers. Stirtec has established an initial client base of satisfied reference customers in both the transportation and industrial sectors, securing high trust in the company. Stirtec wants to be the clear market leader in Europe for friction stir welding for industrial applications, serving globally active customers.

Friction Stir Welding

Friction Stir Welding (FSW) is an innovative solid state joining process for metals that is highly superior compared to conventional fusion welding. It is an efficient and clean process and ensures high quality of joints. The process is widely known in research organisations and was so far established for aluminium and titanium in demanding industries like space and aerospace. But FSW of steel, especially high-strength steel, has been considered as not mature enough for industrial application until now, mainly for the lack of adequate - meaning reliable, economic joining tools.

Significant progress was achieved in recent R&D initiatives, regarding the stated objective of "taking the most important next steps needed to successfully accelerate commercialization of FSW technology for high strength steels". Various thicknesses up to 15 mm of different steel grades (e.g., DH-36, 304L, 316L, HSLA-65, S690 and X65) were friction stir welded during the last years. Today's FSW process technology can be applied in single or double pass technique for both similar and dissimilar materials on a multitude of joint configurations (i.e., butt, "T", splice, lap joints, etc.). Thermally induced distortions after welding are low as well as residual stresses, leading to high-quality joints.

Refill Friction Stir Spot Welding (RFSSW)

Refill FSSW is a solid-state joining process developed and patented by Helmholtz-Zentrum Hereon (previously Helmholtz-Zentrum Geesthacht), partner in Stir4Steel project.

Unlike FSW, there is no traversing motion associated with the Refill FSSW process, which results in a spot-like weld.

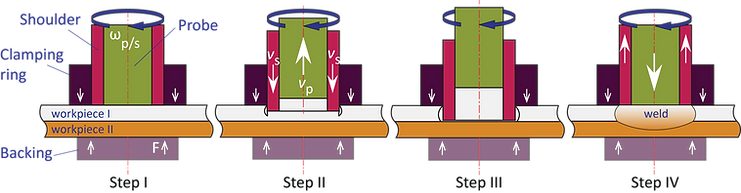

The process uses a non-consumable tool comprising one non-rotating component, clamping ring, and two rotating components, probe and shoulder. Typically, Refill FSSW involves four stages. In the first stage, the tool moves to the surface of the top workpiece - the clamping ring holds the workpieces against the backing. In the second stage, the shoulder rotates and plunges into the workpiece(s) to a desired depth, while the rotating probe simultaneously moves upwards, allowing accommodation for the displace material. In the third stage, the shoulder and the probe keep rotating at the desired positions for a short duration of time to further plasticize the material. Finally, the weld cycle finishes when the rotating components return to the initial positions, consolidating the weld material and resulting in a keyhole-free joint.

In comparison with the established spot-like joining technologies, Refill FSSW offers many benefits, such as improved surface quality, enhanced mechanical properties, environment compatibility, ease of automation. It also allows for re-welding of defective welds in production (simply by repeating the welding operation) with no performance penalty.

FSW and RFSSW in Stir4Steel

In the project Stir4Steel, the consortium tackles the solid-state joining of steel and aluminum-steel as a key enabling technology for many industries. The first part of the project deals with the development of Friction Stir Welding of steel components as well as stitch welding of aluminum to steel. The second part of the project is about the development of Refill Friction Stir Spot Welding (Refill FSSW) for different material combinations and applications, especially for aluminum with steel.

Stir4Steel combines deep FSW and Refill FSSW process expertise with the matching tool strategy and the application knowledge to demonstrate the industrial applications of FSW and Refill FSSW for steel and aluminum to steel parts with high industrial relevance today and in the future.